Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

How can we help?

Our Fiber Laser Handheld Welding Machine is a versatile 3-in-1 solution designed for precision welding, cutting, and cleaning applications. With advanced fiber laser technology, this machine delivers high-speed welding, uniform weld quality, and efficient material processing for stainless steel, mild steel, and aluminum. It is widely used in manufacturing, automotive, aerospace, shipbuilding, and industrial maintenance.

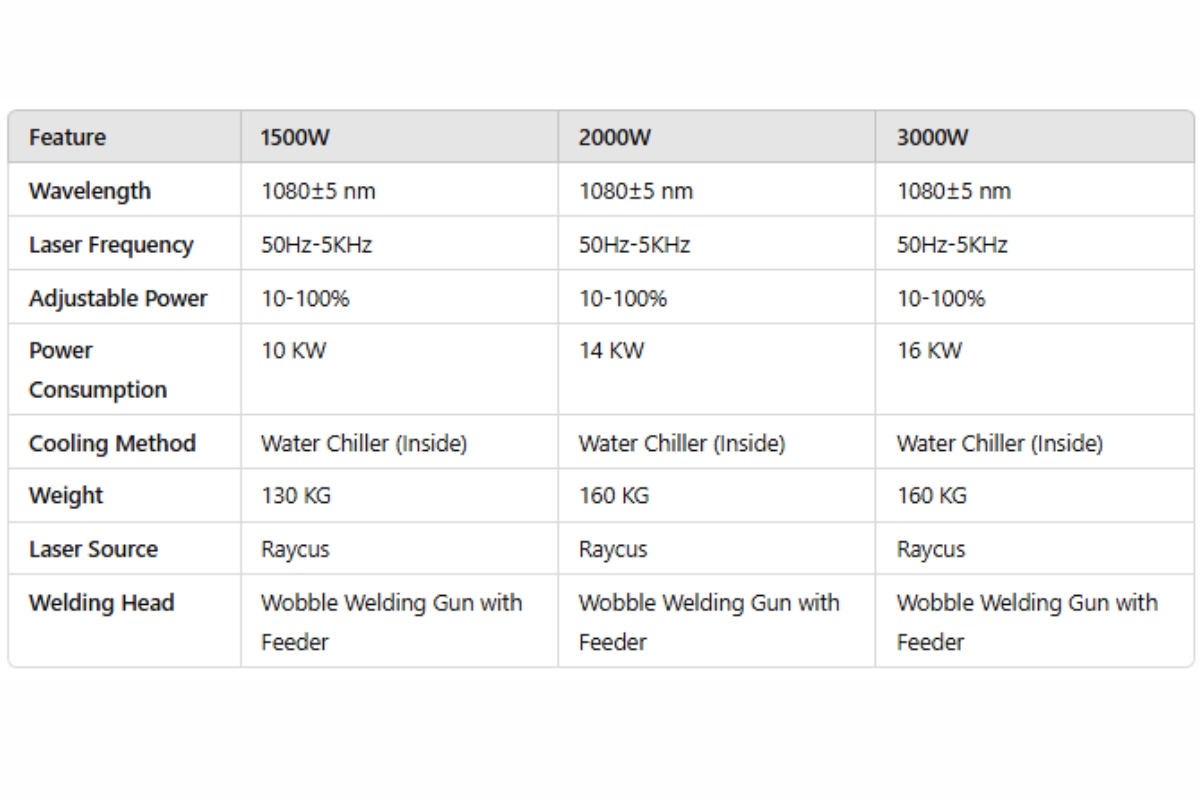

Technical Specifications

Our Solutions & Benefits

We provide high-precision laser welding, cutting, and cleaning services using advanced fiber laser technology. Our expert team ensures seamless results, minimal material distortion, and cost-effective solutions for diverse industrial needs.

- Multi-Functionality – Performs welding, cutting, and cleaning in a single machine for maximum efficiency.

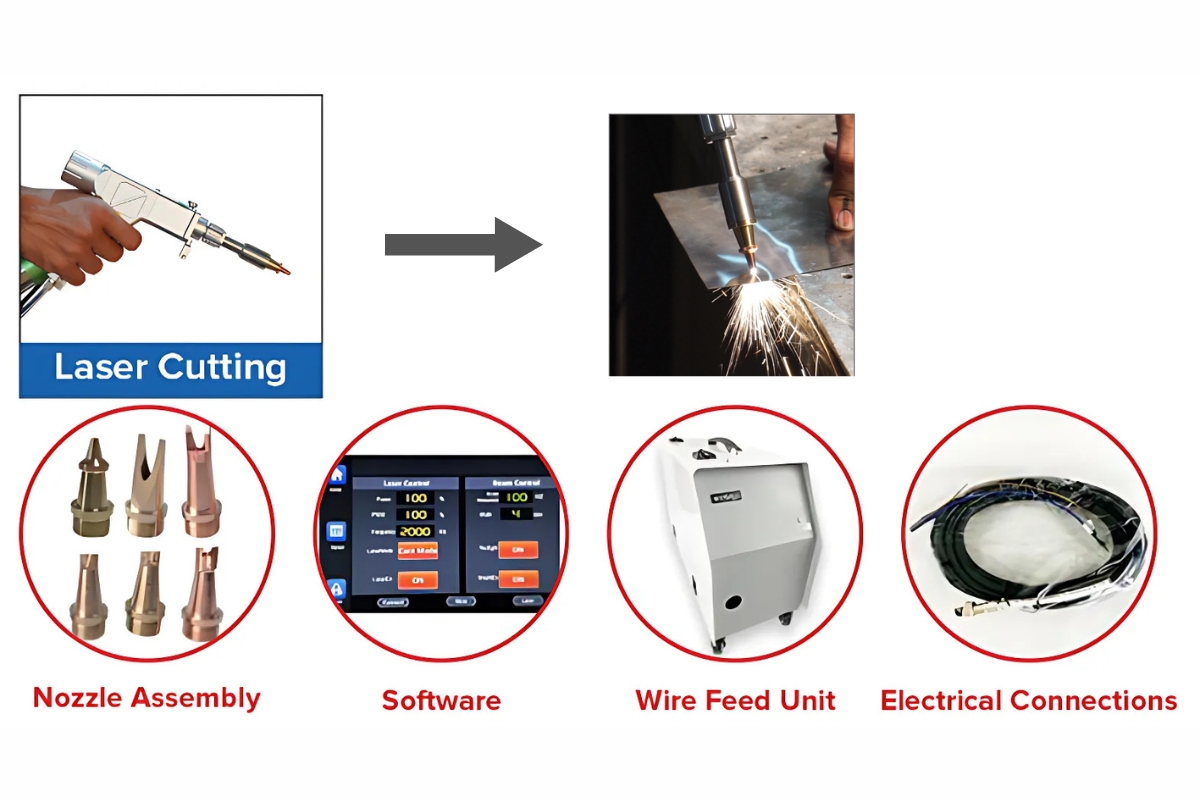

- Precision Cutting – Cuts various metals up to 2-4mm thickness with accuracy and speed.

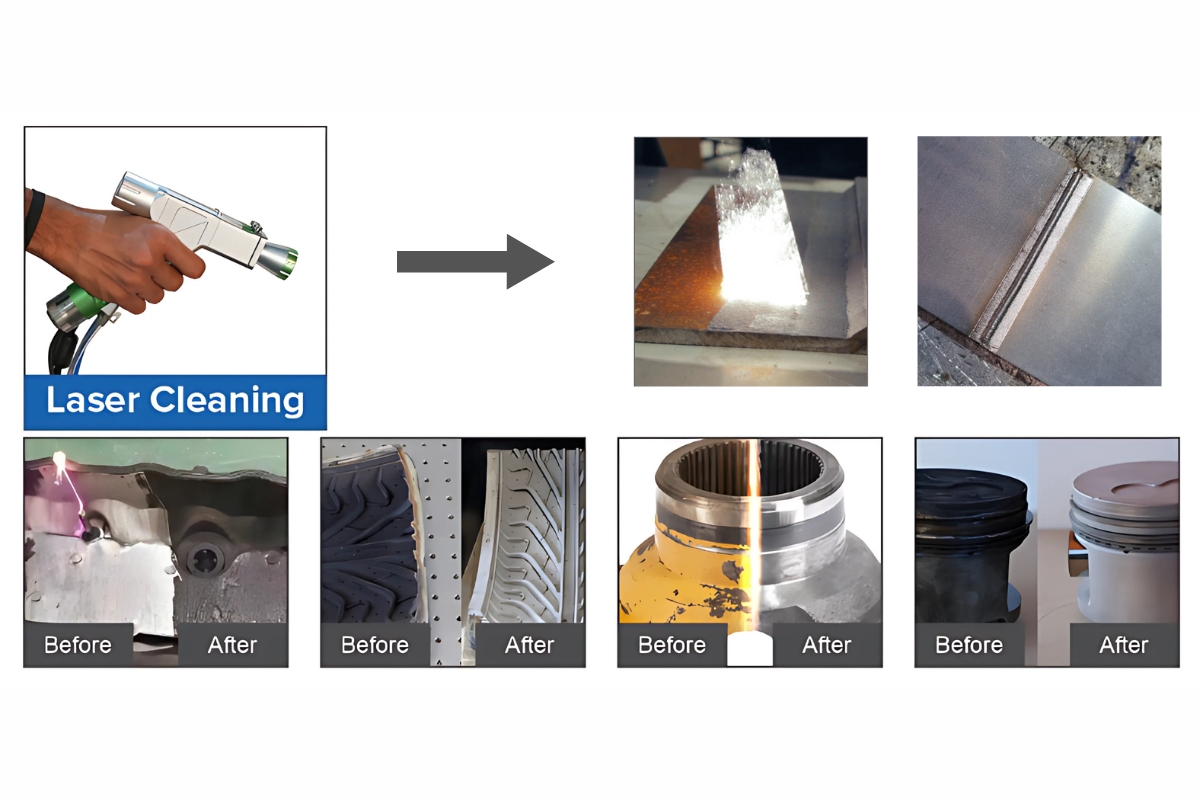

- Eco-Friendly Cleaning – Removes rust, paint, and contaminants without chemicals or consumables.

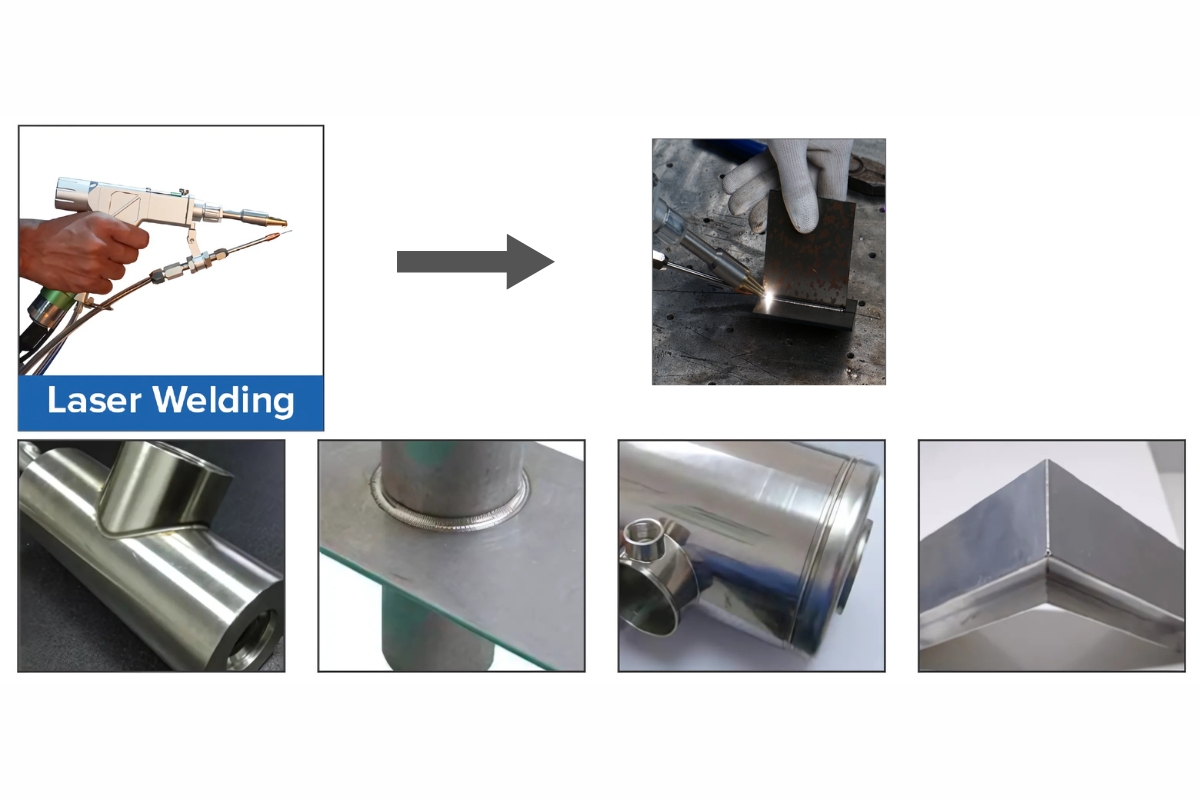

Spot & seam welding with high strength and deep penetration.

Cuts mild steel, stainless steel, and aluminum efficiently.

Removes paint, rust, oil, and other contaminants.

Eliminates chemical cleaning, ensuring a safe and efficient welding process.

What is Included

We offer laser welding, cutting, cleaning, and seam cleaning services for various industries, including automotive, aerospace, fabrication, and industrial manufacturing.

We specialize in stainless steel, mild steel, aluminum, copper, brass, and other metals, ensuring precise and high-quality results.

Yes! We offer tailor-made solutions based on your project requirements, whether it's precision welding, intricate cutting, or surface cleaning for different applications.

Our fiber laser technology provides faster processing, higher precision, minimal material distortion, and a cleaner finish without the need for additional consumables.

Simply contact us with your project details, including material type, thickness, and job specifications, and we’ll provide a competitive quote based on your requirements.