Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

How can we help?

At Georubric Engineers Pvt Ltd, we offer high-precision battery cell spot welding services for lithium-ion battery packs, EV batteries, and energy storage systems. Our advanced spot welding technology ensures strong, reliable, and highly conductive welds, enhancing battery performance and longevity.

With automated CNC-controlled machines, we guarantee consistent and accurate welding, reducing defects and improving efficiency for high-volume battery production.

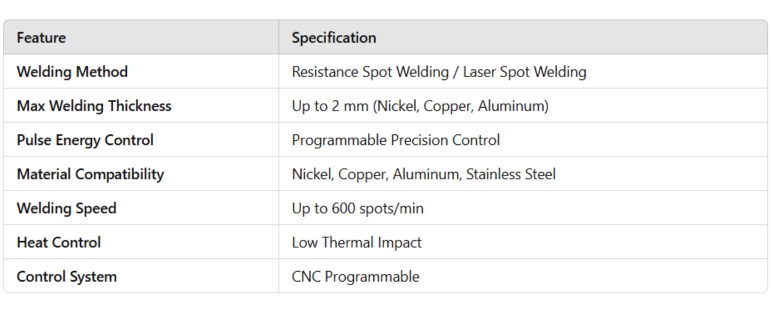

Technical Specifications

Our Solutions & Benefits

Our battery cell spot welding services provide fast, efficient, and durable metal joining, ensuring high performance in battery pack manufacturing.

- High Precision & Repeatability – Ensures consistent weld quality, minimizing defects and rework.

- Optimized Conductivity & Strength – Guarantees low electrical resistance for enhanced battery efficiency.

- Non-Damaging Heat Application – Minimizes thermal impact on cells, ensuring battery safety and longevity.

Used for battery pack assembly, this process ensures strong, conductive, and durable welds between nickel strips and battery terminals.

A specialized technique for EV batteries and high-power storage systems, ensuring secure connections between busbars and battery cells.

Perfect for high-capacity battery modules, allowing precise stacking and welding of multiple layers for superior conductivity and mechanical strength.

What is Included

Spot welding ensures strong, conductive connections while minimizing heat damage to battery cells, making it ideal for lithium-ion battery packs.

We can weld nickel, copper, and aluminum—the most commonly used materials in battery pack assembly.

Yes! Our CNC-controlled spot welding machines allow for automated, high-speed production with consistent quality.

It ensures low electrical resistance, enhancing energy transfer efficiency and battery durability.

Contact us with your project specifications, and our team will provide a customized welding solution.