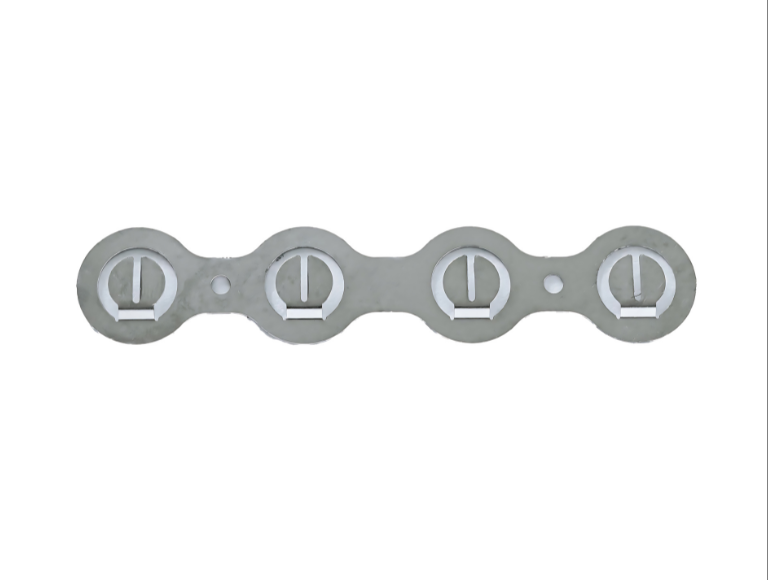

Sandwich Busbar

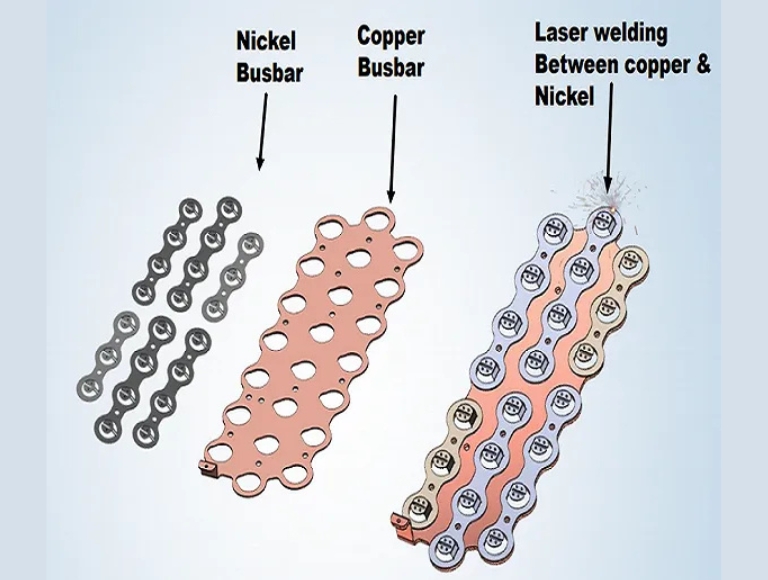

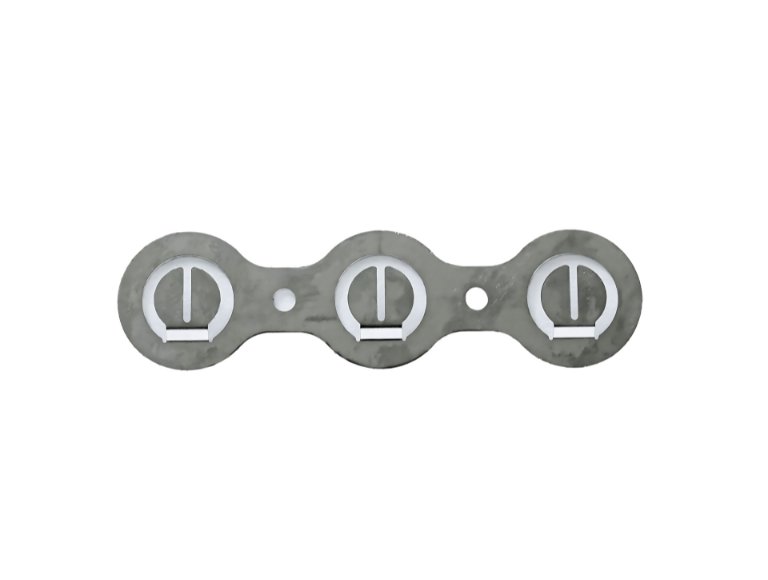

The Sandwich Cu-Ni Busbar combines high-conductivity ETP Copper with corrosion-resistant Nickel Ni-200, precision laser-welded for durability. Its layered design ensures efficient power transmission, making it ideal for power generation, renewable energy, and industrial applications.

Frequently Asked Questions (FAQs)

The combination of Copper and Nickel provides excellent conductivity, durability, and corrosion resistance, making it ideal for high-performance applications.

Laser welding ensures a seamless bond between the copper and nickel layers, providing a strong, stable, and long-lasting electrical connection.

Yes, the Nickel Ni-200 layer protects against oxidation, corrosion, and harsh weather conditions, making it perfect for outdoor and industrial use.

Yes! We offer customized sizes, thicknesses, and configurations to match your requirements.

Industries such as power generation, renewable energy, industrial automation, aerospace, and automotive rely on Cu-Ni busbars for reliable and efficient power distribution.

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

About the Product

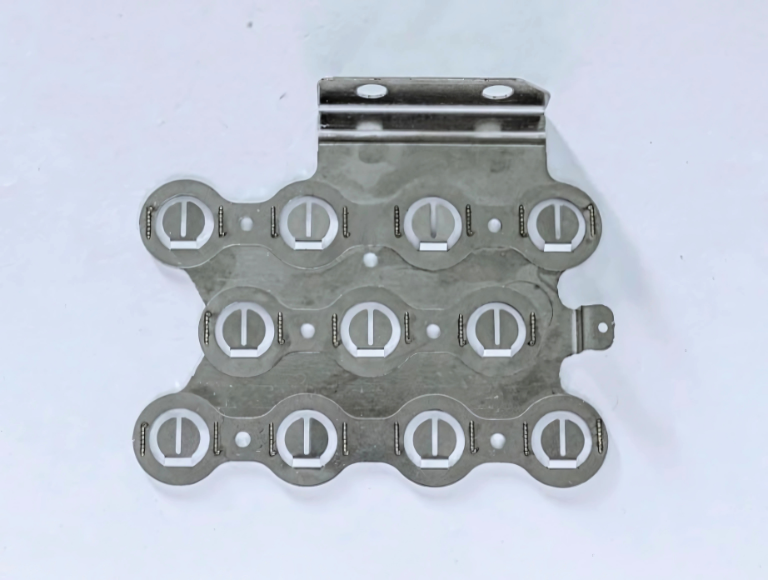

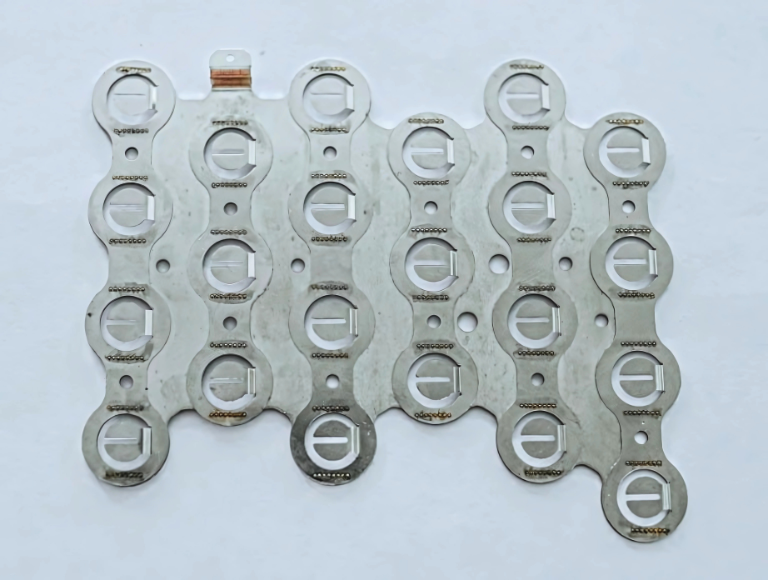

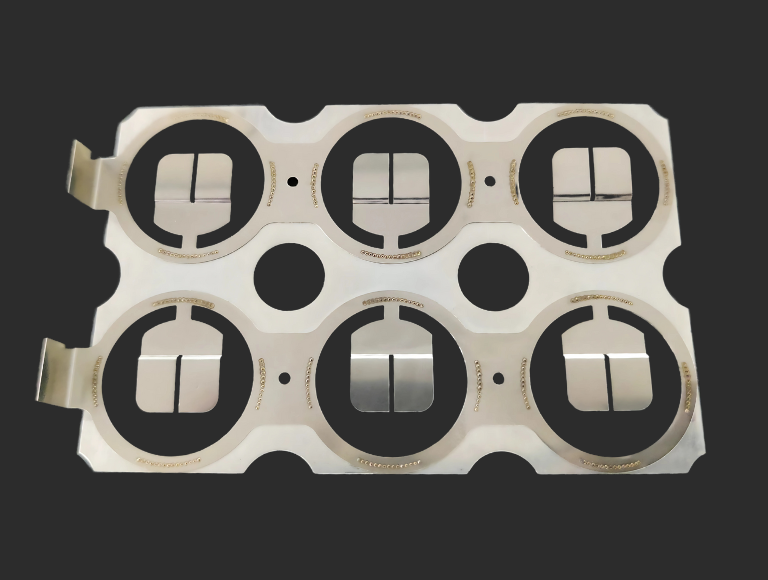

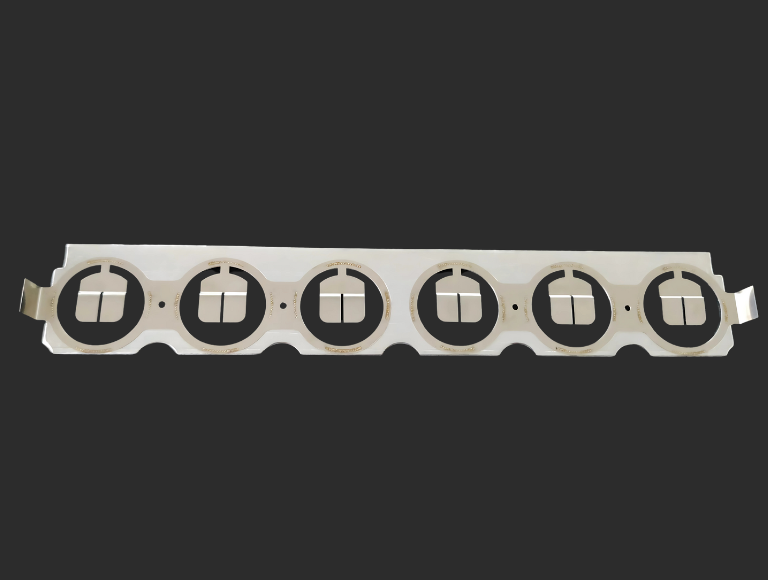

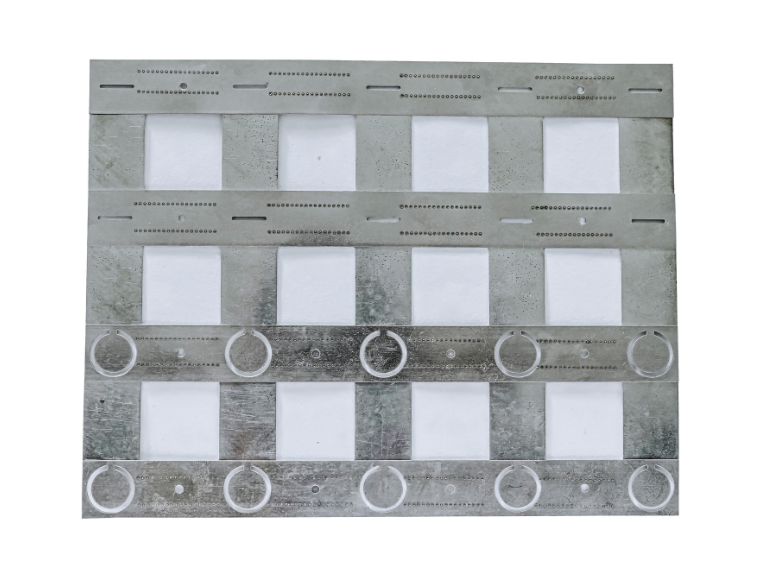

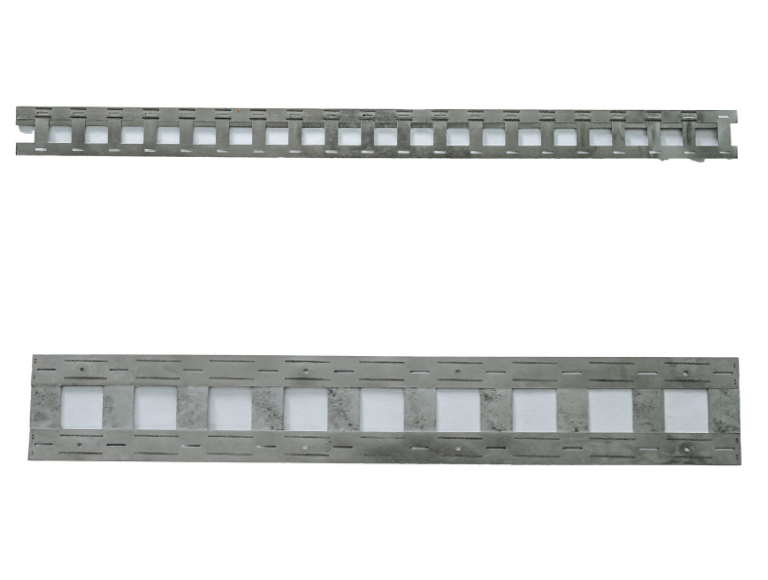

The Sandwich Cu-Ni Busbar is a high-performance power distribution solution engineered for applications that demand exceptional electrical conductivity, mechanical strength, and corrosion resistance. Designed for high-efficiency energy transfer and long-term reliability, this busbar is manufactured using 99.9% pure ETP Copper (available in thicknesses ranging from 0.6 mm to 1 mm) and Nickel Ni-200 (0.2 mm thickness).

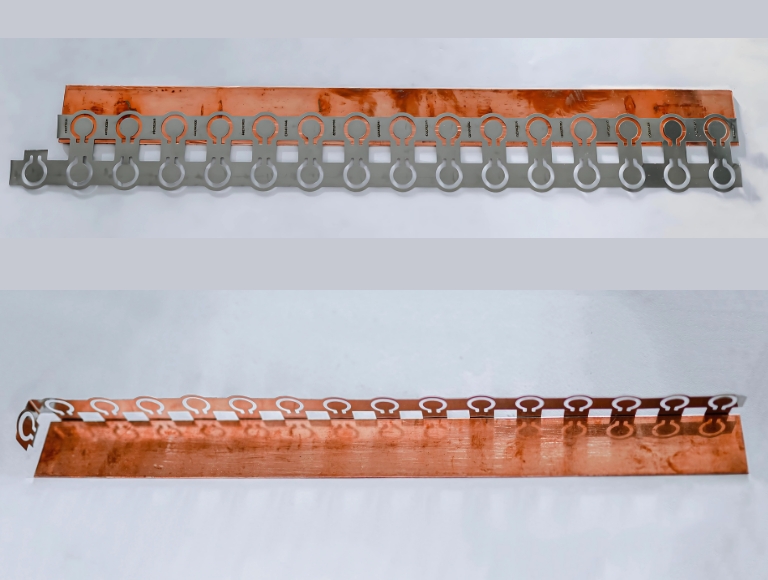

The sandwich structure, created through precision laser welding, ensures a seamless bond between the copper and nickel layers, eliminating weak points, improving electrical conductivity, and enhancing thermal management. The integration of nickel adds superior oxidation and corrosion resistance, making the busbar suitable for harsh environments, high-current applications, and extreme operating conditions.

By integrating cutting-edge materials and precision engineering, the Sandwich Cu-Ni Busbar delivers superior efficiency, durability, and adaptability, making it the preferred choice for engineers and manufacturers worldwide.

Our Approach & Solution

We leverage precision laser welding and advanced manufacturing techniques to create high-performance Sandwich Cu-Ni Busbars. Our approach ensures seamless bonding of ETP Copper and Nickel Ni-200, optimizing conductivity, durability, and corrosion resistance.

By focusing on low energy loss, superior heat dissipation, and long-term stability, we deliver custom-engineered solutions tailored to demanding industries such as power generation, renewable energy, EV battery systems, and aerospace. Our commitment to quality, innovation, and precision engineering guarantees high-reliability power distribution solutions that exceed industry standards.

- Precision Laser Welding for Seamless Bonding

- Optimized Cu-Ni Composition

- Efficient Power Transmission

- Corrosion & Heat Resistance

Ensures efficient energy transfer in substations, transformers, and electrical grids.

Enhance solar, wind, and energy storage solutions with long-lasting performance.

Supports high-power industrial equipment, ensuring stable electrical connections. Used in lightweight, high-performance electrical systems where corrosion resistance is critical.

Frequently Asked Questions (FAQs)

The combination of Copper and Nickel provides excellent conductivity, durability, and corrosion resistance, making it ideal for high-performance applications.

- Laser welding ensures a seamless bond between the copper and nickel layers, providing a strong, stable, and long-lasting electrical connection.

Yes, the Nickel Ni-200 layer protects against oxidation, corrosion, and harsh weather conditions, making it perfect for outdoor and industrial use.

Yes! We offer customized sizes, thicknesses, and configurations to match your requirements.

Industries such as power generation, renewable energy, industrial automation, aerospace, and automotive rely on Cu-Ni busbars for reliable and efficient power distribution.