Nickel Busbar

Are you seeking a high-performance busbar solution for your industrial or energy applications? Contact us today! Our team is ready to provide customized Nickel Busbars tailored to your project requirements.

Frequently Asked Questions (FAQs)

We manufacture custom CNC-machined copper components, including busbars, terminals, connectors, and switchgear parts.

Plated copper parts offer enhanced corrosion resistance, improved conductivity, and better durability in electrical systems.

Yes! We provide fully customized solutions based on your technical drawings and specifications.

These parts are used in electrical switchgear, transformers, control panels, power distribution, and automotive industries.

Contact us with your design and performance requirements; our experts will guide you to the best solution.

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

About the Product

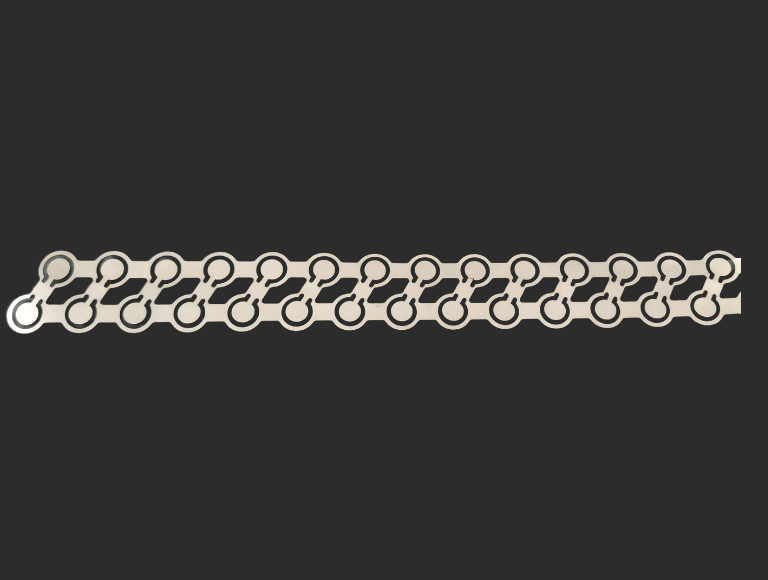

The Nickel Busbar is engineered for high-performance electrical applications, offering exceptional conductivity and corrosion resistance. Manufactured from high-purity Nickel-plated Copper (Cu-Ni 99.9%), this busbar ensures minimal electrical resistance while maintaining long-term stability in harsh environments.

With a precisely controlled thickness, the Nickel Busbar provides optimal mechanical strength and flexibility, making it the preferred choice for electric vehicles (EVs), battery management systems (BMS), power distribution networks, and industrial automation. Its superior oxidation resistance enhances performance in extreme temperature and high-humidity conditions, ensuring reliable power transmission and reduced energy loss.

The Nickel Busbar delivers unmatched electrical efficiency, durability, and sustainability, whether used in EV batteries, renewable energy systems, or aerospace applications.

Our Approach & Solution

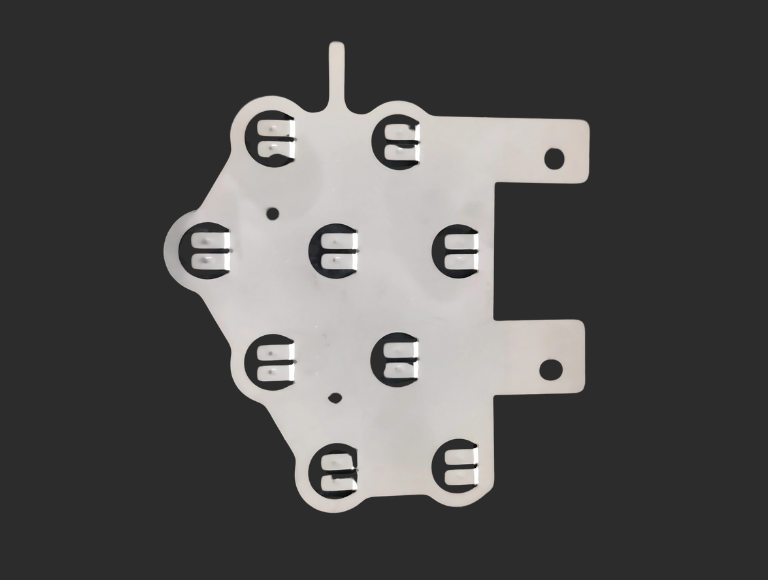

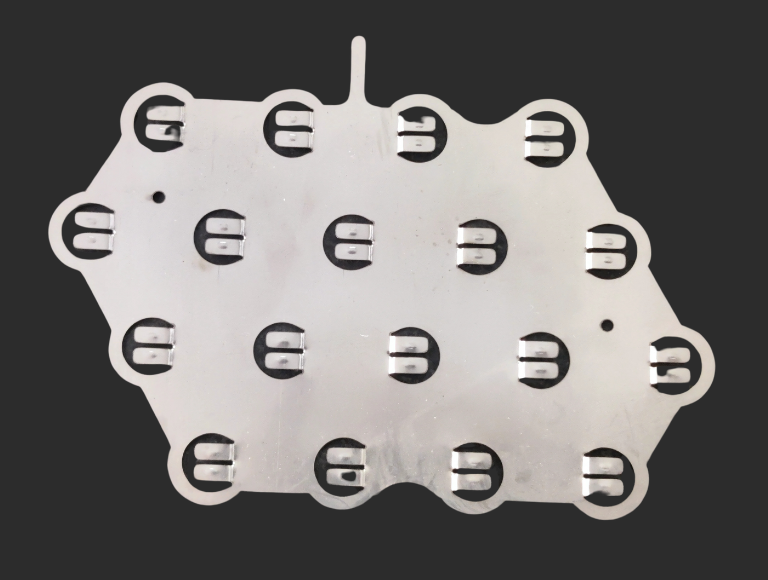

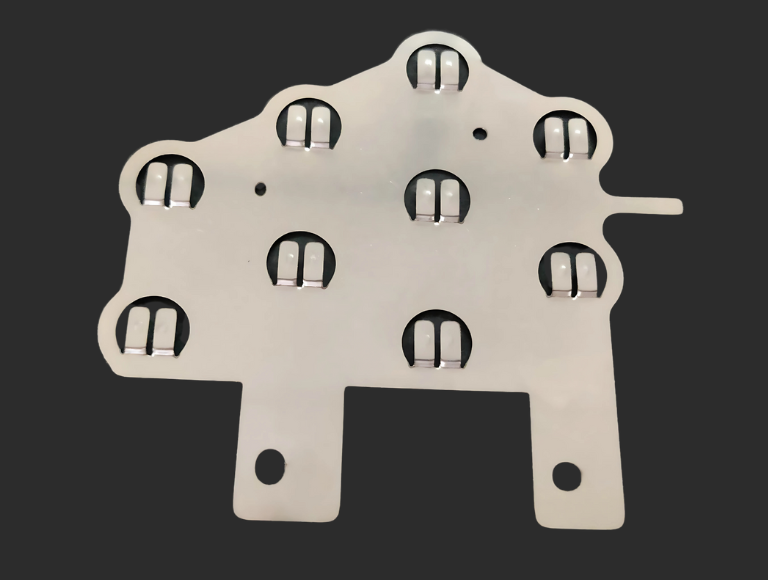

At Georubric Engineers Pvt Ltd, we specialize in advanced nickel-plating and precision machining techniques to manufacture premium-quality Nickel Busbars. Our innovative fusion welding and ultrasonic bonding methods ensure low contact resistance, high thermal stability, and superior durability.

We work closely with clients to develop customized busbar solutions for high-voltage, high-temperature, and high-efficiency electrical applications.

- Exceptional Corrosion Resistance – Nickel plating prevents oxidation, ensuring long-lasting performance in harsh environments.

- Superior Conductivity – High-purity copper core with nickel coating minimizes resistance for improved energy efficiency.

- High Temperature & Chemical Resistance – Ideal for demanding industrial, aerospace, and energy applications.

Best suited for EV batteries, power distribution, and electrical panels with high thermal conductivity.

Engineered for aerospace, renewable energy, and industrial power systems requiring extreme durability.

Designed for high-voltage applications, offering superior mechanical strength and oxidation resistance.

Frequently Asked Questions (FAQs)

Nickel Busbars provide superior corrosion resistance, oxidation protection, and higher temperature tolerance, making them ideal for high-performance applications like EV batteries, aerospace, and power grids.

- Nickel plating enhances conductivity while preventing oxidation and degradation, ensuring long-term stability in harsh environments and high-voltage systems.

Industries such as electric vehicles (EVs), renewable energy, aerospace, battery management systems (BMS), and industrial automation widely use Nickel Busbars for superior electrical efficiency and durability.

Yes, Nickel Busbars are highly resistant to heat, moisture, and chemical exposure, making them suitable for outdoor and high-demand electrical environments.

Absolutely! We offer custom thicknesses, hole patterns, nickel-silver plating, and flexible or rigid designs based on your specific application needs.